POPCORN

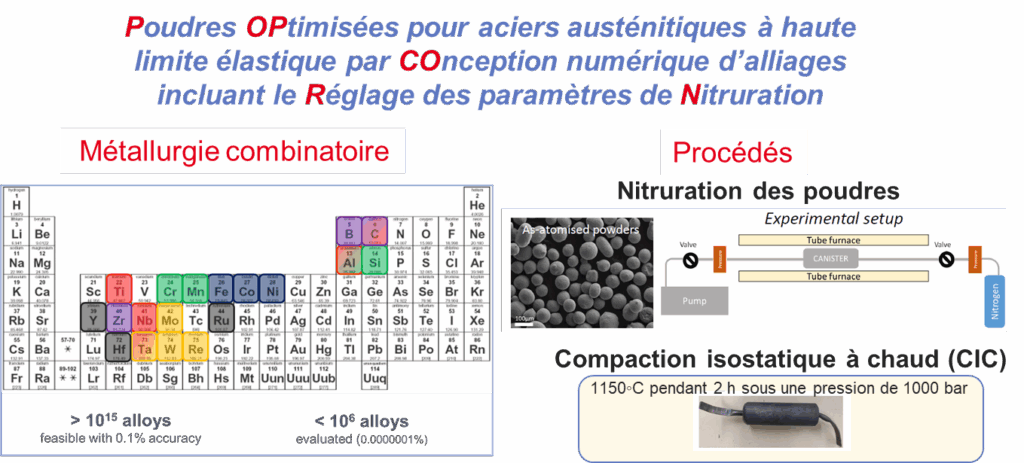

Optimized powders for high elastic limit austenitic steels by digital design of alloys including adjustment of nitriding parameters

Leader : Clara Desgranges

The POPCORN project aims to design, while respecting eco-design constraints, new austenitic stainless steel chemistries tailored to the specific conditions experienced by the part in service and adapted to its manufacturing method: in this case, powder metallurgy for parts requiring a high yield strength, obtained by controlled nitriding, then densified by CIC. The project offers a comprehensive demonstration of the methodology: from digital design on a wide range of possible compositions, based in particular on massive CALPHAD calculations for some of the design criteria, to mechanical testing of a few grades thus optimized, developed, and formed.

The core of the digital design phase will rely on massive CALPHAD calculations in the Fe-Cr-Ni-Mo-X-N-C system. These calculations will be performed at the DES (ISAS/DRMP/S2CM). The search for the most promising austenitic steel compositions will be carried out by multi-criteria optimization, based on the expertise of DRT/List, from which the grades to be studied experimentally will be chosen. The experimental part will be carried out at DRT/LITEN in Grenoble on the nitriding bench and using the CIC of Equipex+ CALHIPSO, as well as the mechanical and metallurgical characterizations in collaboration with an academic laboratory.