MIROMET

Evaluation of the role of surface microstructure in the corrosion resistance of metallic materials (collaboration with ONERA)

Leader : Fabien Rouillard

Background:

Materials used in energy conversion units, such as hydrogen electrolyzers and fuel cells, are exposed to aggressive environments (air, H2/H2O gas mixtures, pressurized water, etc.). Their corrosion resistance depends on the formation of a uniform, slow-growing oxide layer. This protective regime often relies on the preferential reaction of an alloying element, such as chromium in stainless steels. Surface microstructure plays a crucial role in this selective oxidation capacity, with grain size being a determining factor. The MIROMET project focuses on understanding the role of surface microstructure in the formation of protective oxide layers and seeks to design more corrosion-resistant materials. The objective is to advise manufacturers on the ideal microstructures for alloys and coatings, particularly in terms of grain shape and size. This project combines experimental work and simulations, conducted in collaboration with the CEA and ONERA.

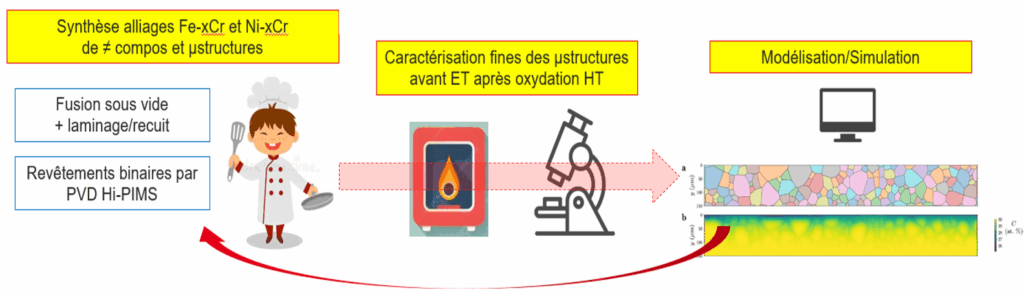

Methodology:

Alloys and coatings of various compositions and microstructures will be synthesized using conventional metallurgy and PVD-HiPIMS (DIADEM-2D). The oxidation behavior of the samples will be studied at different temperatures (300-900°C), and the oxide layers will be analyzed using various analytical techniques (scanning electron microscopy, transmission electron microscopy, X-ray diffraction, etc.). Experimental results will be compared with simulations obtained using COMSOL software and internally developed codes.