LTM-OPTIMA

Collaboration with NTU Singapore

Lightweight Tough Metamaterials for Optimized Performance Through Innovative Manufacturing Approaches

Leader: Daniel Bonamy

The LTM-OPTIMA (Lightweight Tough Metamaterials for Optimized Performance Through Innovative Manufacturing Approaches) project is developing ultralight metallic metamaterials for the aerospace, transportation, and energy sectors. It builds on previous experiments conducted at IRAMIS and IRFU/DIS at the CEA to address challenges related to metastructure anisotropy.

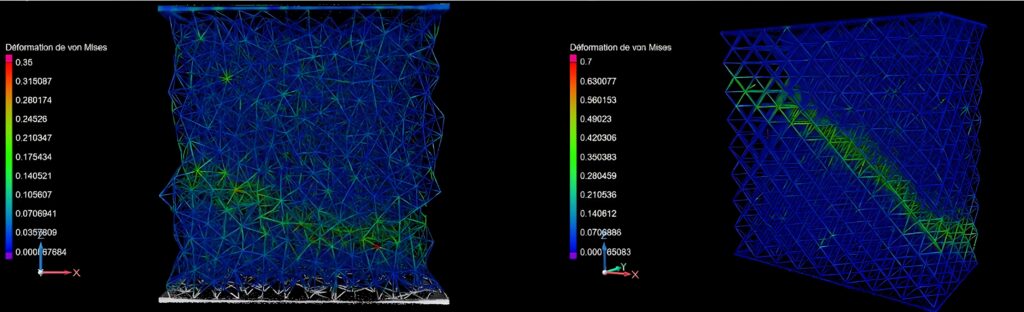

The objective is to design complex metallic metastructures, such as Delaunay-type lattices, combining local isotropy and optimized mechanical performance. A “material-by-design” approach, driven by artificial intelligence, will optimize geometry and architecture based on specific constraints.

The project utilizes several metal additive manufacturing technologies (MBJ, MEX, EB-PBF, L-PBF) to produce these high-performance metamaterials. A comparative benchmark will assess the ability of these processes to manufacture complex structures while controlling porosity and maximizing mechanical properties.

The materials study will combine thermomechanical analyses, compression tests, and advanced characterization (SEM, X-ray tomography) to assess porosity, internal connectivity, and mechanical behavior. Finite element simulations integrated from the design stage will help predict performance and guide optimization.

Innovative surface treatments, such as pack-cementation and DLI-MOCVD, will enhance durability by improving wear and corrosion resistance.

In situ tests will be conducted using the Hexapod platform of the PEPR DIADEM, at CNRS 3SR Grenoble, to analyze deformation under multiaxial loading in real time and explore the link between microstructure and mechanical properties. These tests will utilize X-ray microtomographs (synchrotron or laboratory sources), allowing in situ 3D observations of mesostructures during loading, at room temperature.

LTM-OPTIMA aims to achieve a dual impact: supporting the energy transition with lighter, more resource-efficient materials, and stimulating innovation in metal additive manufacturing. The associated thesis, co-supervised by Nanyang Technological University (NTU) in Singapore, reinforces the project’s international reach.

As part of the PEPR DIADEM doctoral program, LTM-OPTIMA aims to become a key player in advanced metamaterials and contribute to the development of sustainable industrial solutions.