4DFAST

4DFAST

Leader: Frédéric Démoly

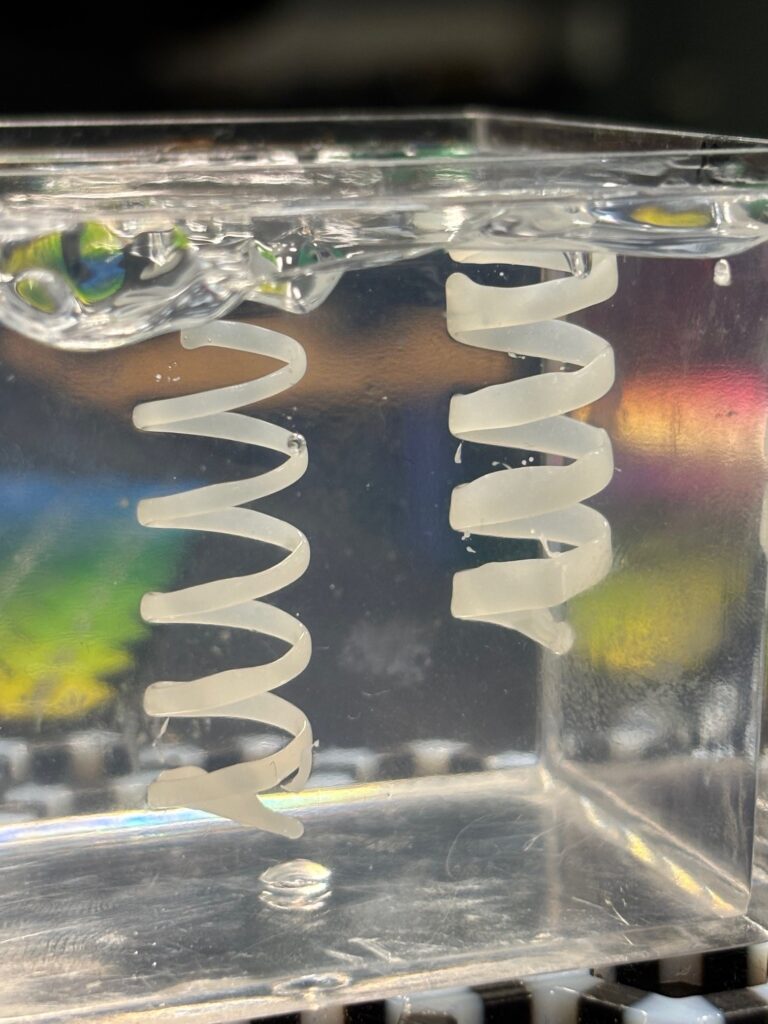

4DFAST Research project develops and innovative 3D/4D Additive Manufacturing method by multi-materials direct extrusion using a 6 axis robotic arm and a temporary support gel to allow the fabrication of complex and morphable structures. Functional inks -elastomers, ceramics, polymers – are solidified using relevant processes (UV, annealing, sintering). The robotic approach needs advanced trajectory algorithms and a real time control based on the vision and automatic learning to ensure a fluid and precise printing. This projects also explores the adhesion between heterogeneous materials via chemical and mecanic strategies and tests various stimuli sensible inks for biomedical applications. This project is in collaboration between several French research units (ICB CNRS, CEA Le Ripault, ICGM CNRS, LCMCP CNRS) and an American University, Georgia Institute of Technology.